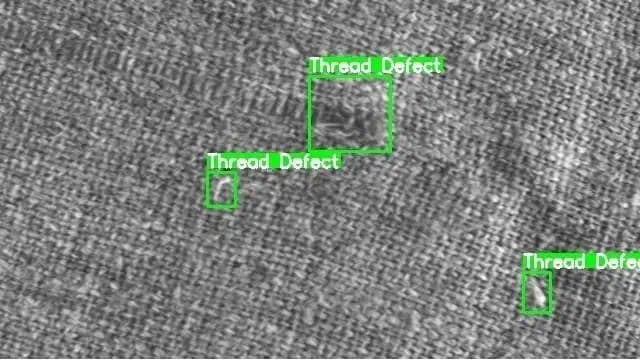

AI Visual Inspection for Defect Detection

Ombrulla’s AI Visual Inspection System for Defect Detection ensures faster, accurate inspections on every production line.

Ombrulla’s AI Visual Inspection System for Defect Detection ensures faster, accurate inspections on every production line.

Ombrulla's AI visual inspection system helps business bring accuracy, speed and consistency in every stage of your quality process. Instead of depending on manual checks where small defects are missed, our system uses advanced computer vision to find issue early and make production runs effectively.

We partner with our clients to design and implement inspection workflows which deliver measurable results and support continuous improvement.

Unlocking next level quality control through our AI Visual Inspection system, a smarter way to detect defects with high accuracy and speed which reduces manual workload helps improve production, consistency and gain real time insights that helps to reduce overall cost and increase production.

Our AI visual inspection system trained with powerful AI defect detection models identify even tiny errors in real time to make sure every product meets the highest quality standards that human inspection simply can’t match.

Our AI analyzes images or videos faster than humans, to make real-time defect detection on high-speed and helps to boost overall productivity.

Our visual inspection system maintains consistent quality control and makes sure every product meets industry standards which reduces risks and prevents costly legal issues.

Our AI visual inspection system converts raw data into actionable insights which highlights performance gaps and defect behaviours so teams can continuously improve operations

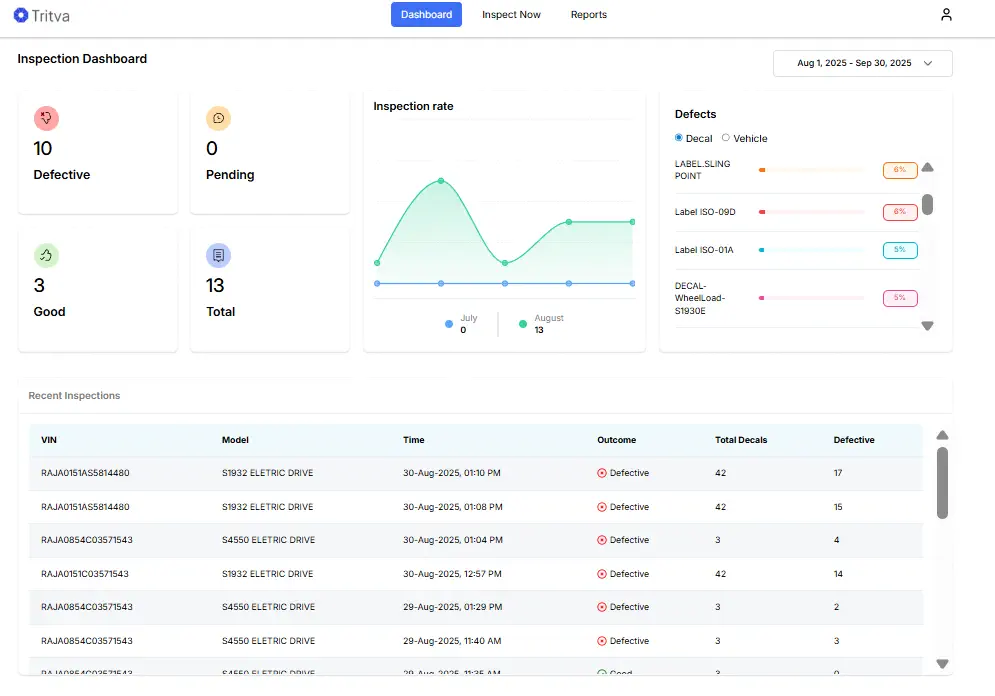

Tritva

TritvaConverts images or videos into immediate defects alerts and useful insights, helps teams lower their expenses, avoid downtime and strengthen safety and compliance.

Discover Tritva, the AI-powered visual inspection platform that transforms manual inspections into AI-driven efficiency

Create accurate AI inspection models with enhanced image quality, noise reduction, and the right algorithms.

Process images and videos instantly to detect defects, classify products, and pinpoint exact issues.

Store all inspection data, monitor dashboards, and generate insightful reports to drive better decisions.

Tritva replaces manual inspections with AI powered visual inspection helping businesses cut cost, speed the production and deliver with consistent quality.

Industries that adopt AI Visual inspection systems for defect detection gain stronger quality control, lower operating costs, and faster production which deliver effective and accurate results that traditional methods can't give.

Ombrulla's AI visual inspection system not only detects defects instead it strengthens your entire product quality. You get faster inspections, reliable decision-ready insights, and consistent output. Each feature is custom made to reduce your rework, protect margins and make sure your production runs with high quality, precision, and predictable performance.

See how Ombrulla’s AI Visual Inspection system can transform your quality control process. Schedule a free consultation with our experts.

Ombrulla enables enterprises to develop and scale AI inspection models with speed and stability. Our engineering approach removes complexity, strengthens security, and gives leadership a dependable foundation for long-term AI growth.

We make raw visual data into High-quality data prepared for AI and control security, compliance and make audits if needed.

Our Ai softwares are trained for your specific needs and updated regularly to stay Correct, reliable, and ready to use

Our AI agents retrieve the right data instantly and use the right tools automatically, enabling faster decisions and smoother inspection workflows.

Distributed compute lets you run AI visual inspections at scale with high performance and controlled infrastructure costs.

Faster inference means faster decisionsour serving setup ensures your inspection models run reliably at any scale.

A unified ML platform that keeps your inspection models trained, optimized, and running smoothlywithout operational friction.

We test every model continuously to make sure everything is safe , consistent and reliable inspection performance in a real production environment.

We safeguard every image and model with strong security controls, ensuring your IP and operations remain fully protected.

AI Visual Inspection is used in various industries to improve quality control and production efficiency. Here are some examples:

Automation production demands perfection . Our ai visual inspection system in automotive manufacturing helps manufactures finds defects in early stage and Protect you from costly mistakes

Tell us about your challenge - we’re here to help.